Innovative Solutions for Wire Processing

Electrical Wire Processing Technology Expo 2024

Visit the show und find state of the art products for hotmelt and wire processing on the Electrical Wire... Read More

New technical center

In order to further expand our customer service, we have rented part of a production facility with an office... Read More

Precise crimping with hand

Hand crimping tools from Kolb are made for crimping all major crimp connectors. The PEW 12 crimping system tool... Read More

Hotmelt machine VRC 601 edrive

Kolb’s newly developed, low pressure VRC 601 edrive encapsulating system with direct hotmelt single-screw extruder is equipped with 3... Read More

Products for Various Applications

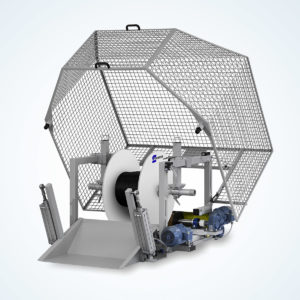

Low pressure moulding machine VRC 601 edrive

Kolb’s newly developed, low pressure VRC 601 edrive moulding system with direct hotmelt single-screw extruder is equipped with 3 heating zones and opens new perspectives for processing different materials, such as polypropylene, polyurethane, co-polyamide, co-polyester, santoprene, TPE, Elastollan, Hytrel. The compact design of this machine with slide table is an innovation in this market segment. The modular structure enables integration in a production line.

The heat-up time is less than 20 minutes; this represents an energy requirement that is approx. 20% lower compared with conventional methods. The electromotive close fixture of the edrive mould additionally increases energy efficiency.