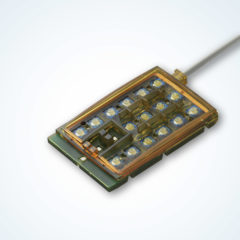

Protection of connections

With hotmelt machines from Kolb, plug connectors, cable ducts and PCBs can be extrusion coated and protected. Kolb offers a cost-effective solution with the hotmelt technology so that connection systems can withstand extreme conditions, such as heat, dust or moisture. Through a low-pressure process components are extrusion coated into their shape and sealed on the wire or on the contact, insulated and mechanically protected.

The easy and safe handling of the systems through the regulated injection time and cooling time provides a high degree of reproducibility in the manufacturing area. Through use of the same tool system that is used for the large machines, tools can be used for other automation steps. Special configurations, such as round table transfer machines, complete workstations with subconstruction or electrical testing of the part to be injected in the tool, are set up is specified by the customer.

Kolb offers you not only the machines and moulds, but also the processing materials suitable for your applications. The experts for hotmelt will be happy to advise you and give you an overview of the numerous hotmelt adhesives.

Hotmelt machine K1002

The Kolb K1002 low pressure moulding machine is configured for medium-size production runs. Through the slide table, the injection time, dwell time and cooling time can be used for removal of parts and fitting the second tool. The K1002 hotmelt machine enables

- automatic procedures of the injection system,

- lateral movement of the injection tool to the second injection position,

- manual movement of the slide table,

- pneumatic tool lock system,

- electronic adjustment of the injection time, dwell time, and cooling time,

- and adapting of all major melting devices.

Technical Data

| Power | 2900 W |

| Molding pressure | up to 40 bar |

| Molding temperature | up to 250 °C |

| Consumption each cycle | approx. 1,5 l |

| Tank capacity | 7 l |

| Electric supply | 230 V and 3x 400 V, 50 Hz |

| Pneumatic supply | 7 bar, dry and oilfree |

| Dimensions (Length x Width x Height) | 1300 x 900 x 1500 mm |

| Weigth | approx. 90 kg |

Brochures

Hotmelt Machine K1002 → PDF

Hotmelt Materials TECHNOMELT → PDF