Kolb offers different feeding devices from Ulmer to optimally feed the cable from the coil or from cable drums to the manufacturing process.

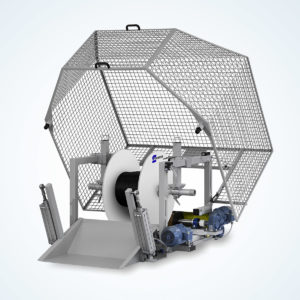

Coil unwinder system SAR

The SAR coil unwinder system was developed as a cable dispenser that delivers material to the processing machines without back-pull. The possibility of a material damaging elongation of the insulation casing in conjunction with the touchless operation sag controller, through this system, is excluded.

The SAR coil unwinder system was developed as a cable dispenser that delivers material to the processing machines without back-pull. The possibility of a material damaging elongation of the insulation casing in conjunction with the touchless operation sag controller, through this system, is excluded.

The material coil is lifted via a pneumatically activated lift shell (option) and rolled by the operator to the two drive axes that close together. One of the axes can be moved through motor power (option) so that the coil slowly lowers into the unwinder. The support cones mounted on the side are moved into the coil bore and thus also permit the processing of slightly defective wooden or plastic coils.

Through the possibility of regulating the unwinding speed either via the touchless DHS1000D loop control or a cable accumulator of the KSP/LSP type series, the overall system can be adapted individually to the respective work process.

Technical Data

| SAR800 | SAR1000 | SAR1250 | |

|---|---|---|---|

| Drive motor | Three-phase motor | Three-phase motor | Three-phase motor |

| Speed | max. 2,0 m/s | max. 2,0 m/s | max. 2,0 m/s |

| Length | 1800 mm | 2000 mm | 2300 mm |

| Width | 1760 mm | 1920 mm | 1980 mm |

| Height | 1320 mm | 1440 mm | 1510 mm |

| Coil size minimum | 400 mm | 500 mm | 600 mm |

| Coil size maximum | 800 mm | 1000 mm | 1250 mm |

| Coil weight maximum | 600 kg | 600 kg | 600 kg |

| Pneumatic supply lifting device | 10 bar | 10 bar | 10 bar |

| Electric supply | 3 x 400 V, 50-60 Hz, 16 A | 3 x 400 V, 50-60 Hz, 16 A | 3 x 400 V, 50-60 Hz, 16 A |

| Adjustable axis | optional | optional | optional |

Brochures

Coil Unwinder SAR → PDF